Pete ya kutupwa ya kutuliza titanium ya titanium

Get Latest Price| Aina ya malipo: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Usafiri: | Ocean,Land,Air |

| Bandari: | NINGBO |

| Aina ya malipo: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Usafiri: | Ocean,Land,Air |

| Bandari: | NINGBO |

Brand: KST

| Aina ya Furushi | : | Mifuko ya Bubble, katoni, sanduku za mbao |

The file is encrypted. Please fill in the following information to continue accessing it

Baridi moto

Tuna utaalam katika:

1. Mchanga wa kutupwa (chuma kijivu, chuma cha ductile, aluminium, nk.)

2. Uwekezaji wa Uwekezaji (chuma cha kaboni, chuma cha pua, chuma cha aloi, nk.)

3. Kufa (aluminium, zinki, nk)

4. Machining (Kituo cha CNC, CNC lathe, lathe, mashine ya kuchimba visima, mashine ya milling, mashine ya kushinikiza, nk)

Cheti: ISO9001: 2015, TS16949

|

Item Name

|

OEM customized rolled ring strainless steel casting die titanium forging part with investment casting

|

||

|

General Products

|

Metal Parts Solution for Vehicle, Agriculturemachine, Construction Machine, transportation equipment, Valve and Pump system, Agriculture machine metal Parts, engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve , valve housing ,Fitting , flange, wheel, fly wheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc.

|

||

|

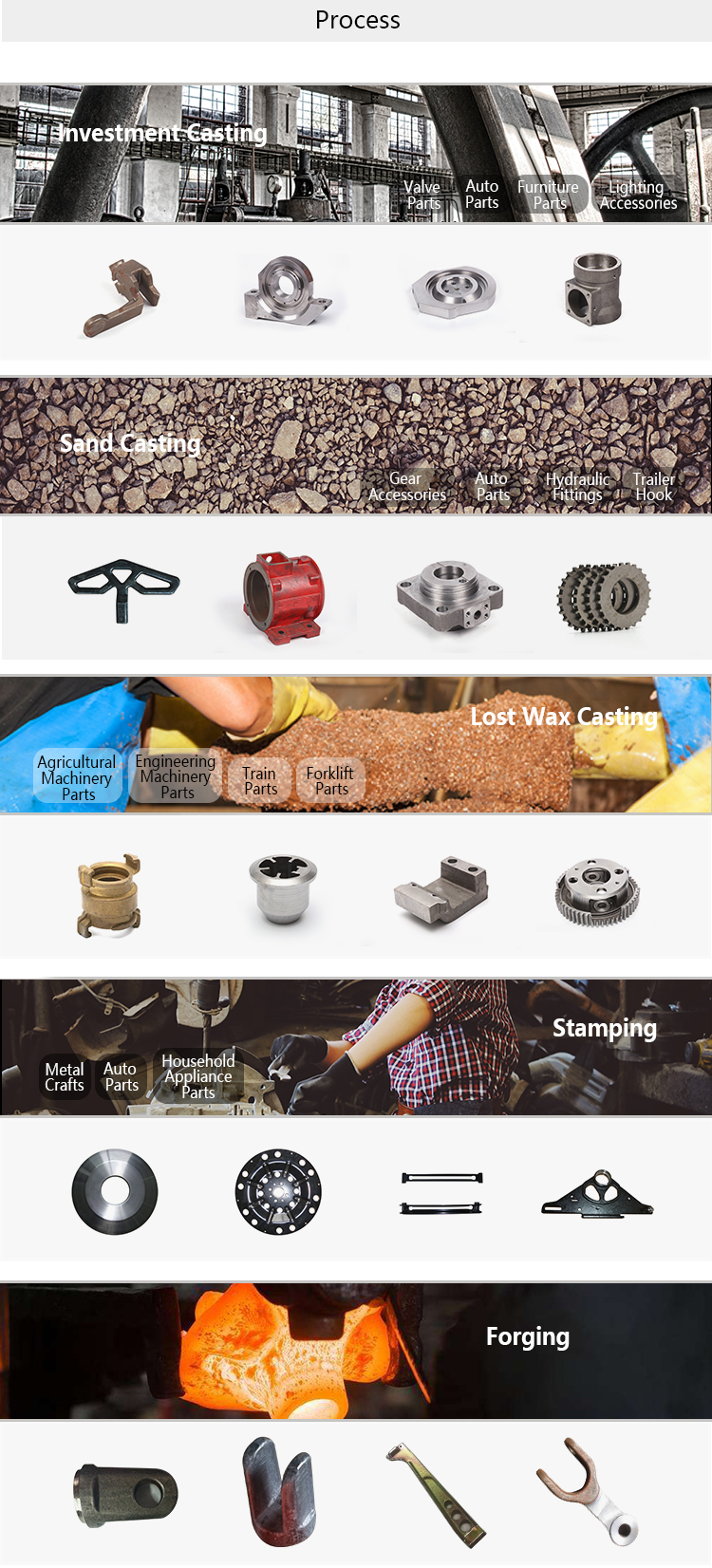

Process

|

Forging , Press

|

||

|

Blanks Tolerance

|

+/-0.3~+/-2 mm

|

||

|

Applicable Material

|

Carbon steel, Low Carbon steel, middle carbon steel, 40Cr, 20CrMnTi, 20CrNiMo etc.

|

||

|

Forging Blank Size

|

142 mm- 300mm or according to customer requirement

|

||

|

Blanks Weight

|

Range from 0.1kg-1000kg

|

||

|

Applicable Machining Process

|

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming etc.

|

||

|

Machining Tolerance

|

From 0.005mm-0.01mm-0.1mm

|

||

|

Machined Surface Quality

|

Ra 0.8-Ra3.2 according to customer requirement

|

||

|

Applicable Heat Treatment

|

Normalization , quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching

|

||

|

Applicable Finish Surface Treatment

|

Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting,

|

||

|

MOQ of mass production

|

100 pcs

|

||

|

Lead Time

|

25~45 days for steel forging metal parts

|

||

Taarifa ya faragha: Usiri wako ni muhimu sana kwetu. Kampuni yetu inaahidi kutofafanua habari yako ya kibinafsi kwa expany yoyote na ruhusa zako wazi.

Jaza habari zaidi ili iweze kuwasiliana na wewe haraka

Taarifa ya faragha: Usiri wako ni muhimu sana kwetu. Kampuni yetu inaahidi kutofafanua habari yako ya kibinafsi kwa expany yoyote na ruhusa zako wazi.